Softening of Water

The only time tested and proven method to soften water is to remove the Calcium and Magnesium ions from the incoming hard water in your home. This is called ION exchange method. There have been many attempts to get away from this process all over the world but without success. Some of these attempts incorporate detaching these ions from the water molecules so that scaling caused by the hard water ions can be avoided, but the total hardness of the processed water remains the same. Some of the methods and claims like the use of electro magnets are blatantly false. LME does not claim to have invented this ion exchange process. It has been there for more than 100 years.

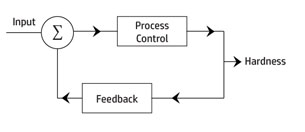

Life Made Ezee is introducing the VERY FIRST closed loop control system that not only displays the hardness of water, it feeds the readings back to the machine and automatically controls the ion exchange process.

-

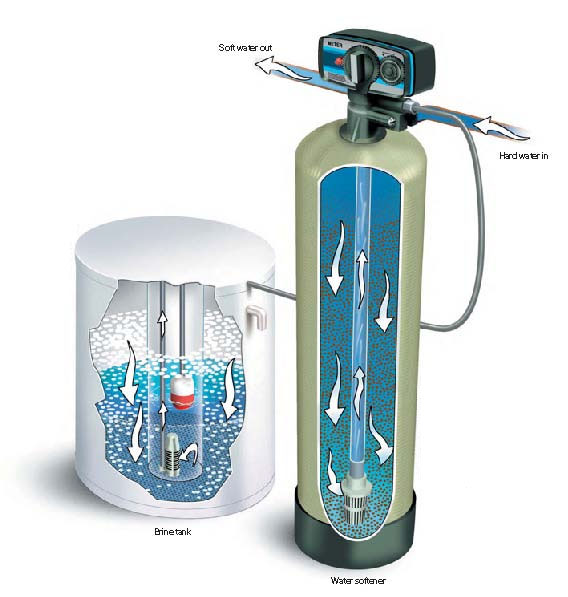

Basics of Resin based Water Softening: In this process, we have a resin tank that contains a fixed amount of liters of a special resin which to a human eye look like small beads of a plastic material. Hard water is made to pass through these beads of resin, called the Resin Bed in the industry. With a controlled flow rate of water through this Resin Bed for a controlled period of contact time with the resin depending upon the hardness of incoming water, the resin removes the Calcium and Magnesium ions from the incoming hard water and the outgoing water is free of these hard water ions replaced with the sodium ions attached to the resin. It is universally accepted that Sodium ions in the amounts relevant to water softening are totally harmless.

Basics of Resin based Water Softening: In this process, we have a resin tank that contains a fixed amount of liters of a special resin which to a human eye look like small beads of a plastic material. Hard water is made to pass through these beads of resin, called the Resin Bed in the industry. With a controlled flow rate of water through this Resin Bed for a controlled period of contact time with the resin depending upon the hardness of incoming water, the resin removes the Calcium and Magnesium ions from the incoming hard water and the outgoing water is free of these hard water ions replaced with the sodium ions attached to the resin. It is universally accepted that Sodium ions in the amounts relevant to water softening are totally harmless. - The Resin bed has a limited capacity to remove the Calcium and Magnesium ions and substitute them with Sodium ions. This capacity depends upon the amount of resin generally measured in liters, the quality of resin, the number of hard ions and the flow rate of the hard water running through the bed. In India, it is generally referred to as OBR that is Output between Regeneration. OBR is measured in liters. After OBR, the resin gets exhausted and hence it can no longer remove the Calcium and Magnesium ions. Think of it has a charge on a battery. A battery has to be recharged constantly. Similarly the Resin Bed has to be re-charged constantly. This recharge or regeneration is accomplished through back washing the resin bed, draining out the removed Calcium and Magnesium ions, and recharging the resin bed with a brine solution to resupply the Sodium ions. The entire regeneration process takes about one hour and is usually scheduled to place at a time convenient to the user. Salt is needed to supply the brine solution for regeneration. Usage and need of new salt depends on the size and design of the water softener. Salt is required to be restocked into the softener every month or so. Resin itself has a limited life measured in years.

-

How does the LME water softening process differ from the current ion exchange methods? Ion exchange softening in India works quite well in a well monitored and controlled processing plant. For example Five star luxury hotels, large hospitals, industrial plants, food processing plants and like have a trained process engineering staff that constantly monitors the hardness of out flowing water as well as the condition of the Resin Bed and supply of brine solution. Hardness is still monitored through the laborious titration method, but it is continuously monitored and corrective action taken primarily through manual regeneration commands and opening and closing of various valves and buffer tanks in the processing plant. Hardness is continuously charted out, but is still subject to human error.

How does the LME water softening process differ from the current ion exchange methods? Ion exchange softening in India works quite well in a well monitored and controlled processing plant. For example Five star luxury hotels, large hospitals, industrial plants, food processing plants and like have a trained process engineering staff that constantly monitors the hardness of out flowing water as well as the condition of the Resin Bed and supply of brine solution. Hardness is still monitored through the laborious titration method, but it is continuously monitored and corrective action taken primarily through manual regeneration commands and opening and closing of various valves and buffer tanks in the processing plant. Hardness is continuously charted out, but is still subject to human error.

Whereas the ion exchange technology has been successfully employed in water processing plants in India, for lack of measurement and monitoring tools and automation, this technology has failed miserably on the Indian sub-continent, for the following reasons, leaving almost all of India with only HARD water for normal household needs like washing your hands, bathing, brushing your teeth, washing your clothes, washing fruits and vegetables, washing your car etc.:

- No Hardness Measurement Meter: Imagine trying to control the temperature of a room if mankind had no means to measure the temperature. Imagine the thermometer has not been invented yet, the thermo-couple or thermistor sensing element does not exist at least at commercially acceptable prices (You would not want to pay a crore of rupees to find out the temperature of your room?). How would you have an affordable air-conditioner? This is the most fundamental problem for application of any water softening technology in India. Not knowing the outcome of your process on a real time basis that is the exact hardness of the outflowing water results in poor performance or no performance of the water softener resulting from lack of timely regeneration, incomplete regeneration, hollow useless regeneration, no regeneration, no refilling of salt, no brine formation and like.

- Shortage of water and power, and non-technical Untrained Installers: Lack of a Hardness measurement meter is further compounded by the need to store water in a sump tank and an overhead tank and still further aggravated by the fact that the power throughout India is intermittent and unreliable. This has forced the current suppliers of ion exchange water softening equipment to violate all basic scientific principles of cat-ion exchange. Untrained non-technical Installers not knowing the science behind cat-ion exchange, further aggravate the situation by installing the softener at the wrong place in the water supply system, for example between the sump tank and the overhead tank. Indian subcontinent is the only place in this world where such an unscientific choice is made in violation of the resin specifications itself, for example a flow rate four to ten times higher than permissible by their own specifications.

- Open Loop Control System: Lack of feedback of the hardness parameter in current water softeners in the Indian subcontinent, results in the process being an open loop control system in the classic definition of control theory. It is like shooting in the dark or driving a car with no visibility hoping that it would somehow reach its destination. This process is fatally flawed with predictable results, that is less than 0.00001% deployment, as compared to almost 99.9% deployment in the United States.

-

THE LME DIFFERENCE: LME WMS employs a close loop control system that monitors the hardness of water outflow and is installed after careful evaluation of the site, by professionally trained LME engineers who totally understand the science and the process. All you have to do is to enter the hardness level acceptable to you and the rest is all taken care of by the WMS. If there is any malfunction in the system, it alerts the user and a corrective action is prompted. But with LME, life is made easy with Total Peace of Mind for the home owner, just like in the US, where hardly anyone faces hard water problems even with 99.9% deployment.

THE LME DIFFERENCE: LME WMS employs a close loop control system that monitors the hardness of water outflow and is installed after careful evaluation of the site, by professionally trained LME engineers who totally understand the science and the process. All you have to do is to enter the hardness level acceptable to you and the rest is all taken care of by the WMS. If there is any malfunction in the system, it alerts the user and a corrective action is prompted. But with LME, life is made easy with Total Peace of Mind for the home owner, just like in the US, where hardly anyone faces hard water problems even with 99.9% deployment.